machining

CNC Machining

Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and CNC routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

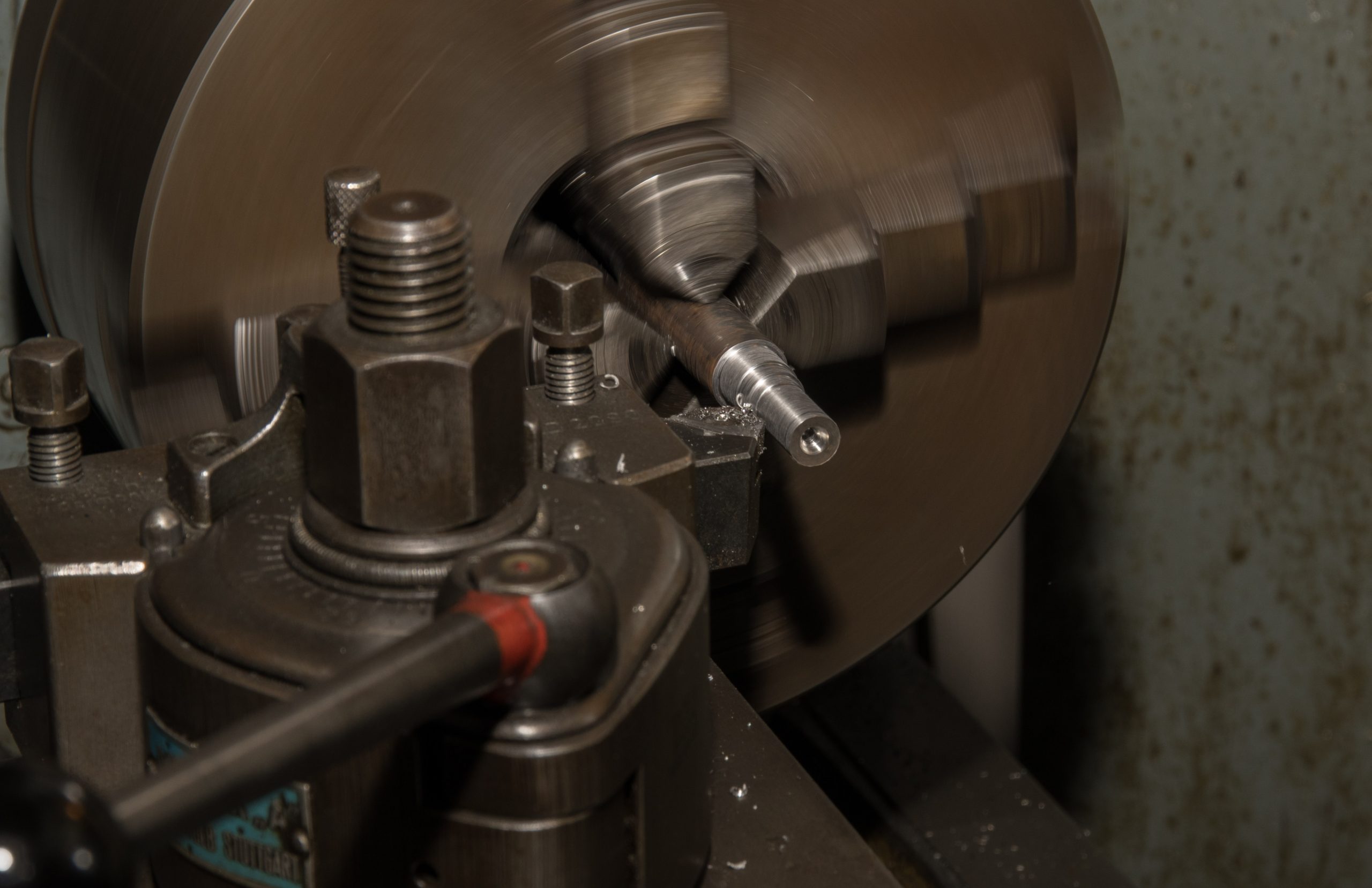

Turning

Turning is the process of using turning lathes to remove material from the outer diameter of a rotating workpiece. Single-point tools shear metal from the workpiece in (ideally) short, distinct, easily recyclable chips.

Milling

Milling is a machining process that involves the use of cutting tools that are rotated at a set speed and then brought into contact with a workpiece. The workpiece is typically held in place by some sort of clamping device. The cutting tools begin to remove material when they touch the workpiece.

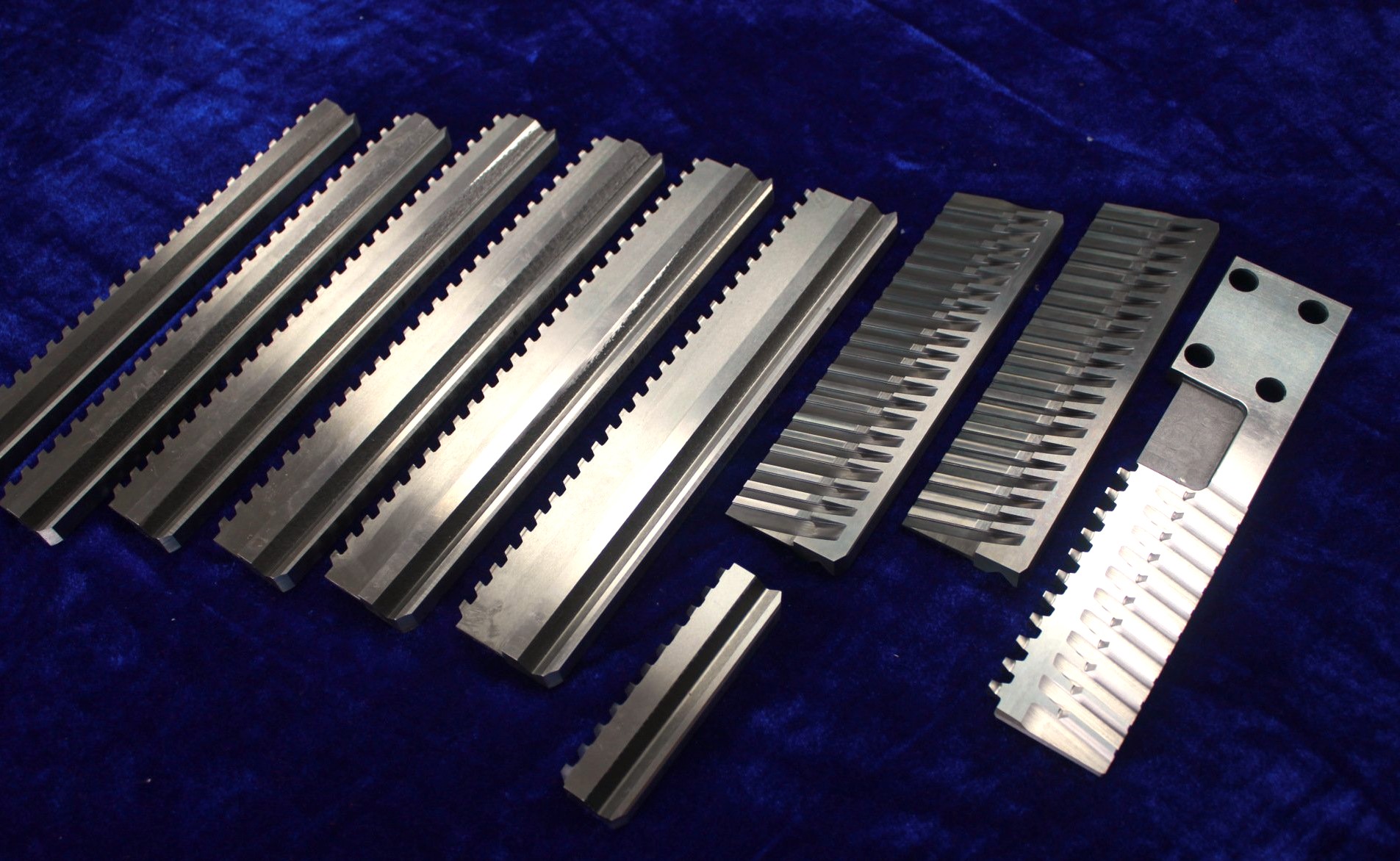

Broaching

Broaching is a machining process where a sharp, hardened, toothed tool removes material from a workpiece in a consistent, continuous, and accurate way. The process of broaching uses a tool with raised teeth of differing sizes that precisely cut away a specified amount of material with every pass over the workpiece.

In broaching, the multi-cutting tool moves while the workpiece remains static, or the workpiece moves while the tool is static. In some cases, there may be relative rotation between the tool and workpiece. The broaching process can be internal through the center of the workpiece or external across the surface of the workpiece.

Fabricating

Fabricating is the creation of metal structures by cutting, bending, assembling, welding and all other necessary machining processes.