edm

Electrical Discharge Machining

The basic electrical discharge machining process is really quite simple. An electrical spark is created between an electrode and a workpiece. The spark is visible evidence of the flow of electricity. This electric spark produces intense heat with temperatures reaching 8,000 to 12,000 degrees Celsius, melting almost anything. The spark is very carefully controlled and localized so that it only affects the surface of the material. The EDM process usually does not affect the heat treat below the surface. The spark always takes place in the dielectric of deionized water. The conductivity of the water is carefully controlled making an excellent environment for the EDM process. The water acts as a coolant and flushes away the eroded metal particles.

Wire EDM

Wire EDM cutting is always through the entire workpiece. To start wire machining, it is first necessary to drill a hole in the workpiece or start from the edge. On the machining area, each discharge creates a crater in the workpiece and an impact on the tool. The wire can be inclined, thus making it possible to make parts with taper or with different profiles at the top and bottom. There is never any mechanical contact between the electrode and workpiece. The wire is usually made of brass or stratified copper and is between 0.1 and 0.3 mm diameter.

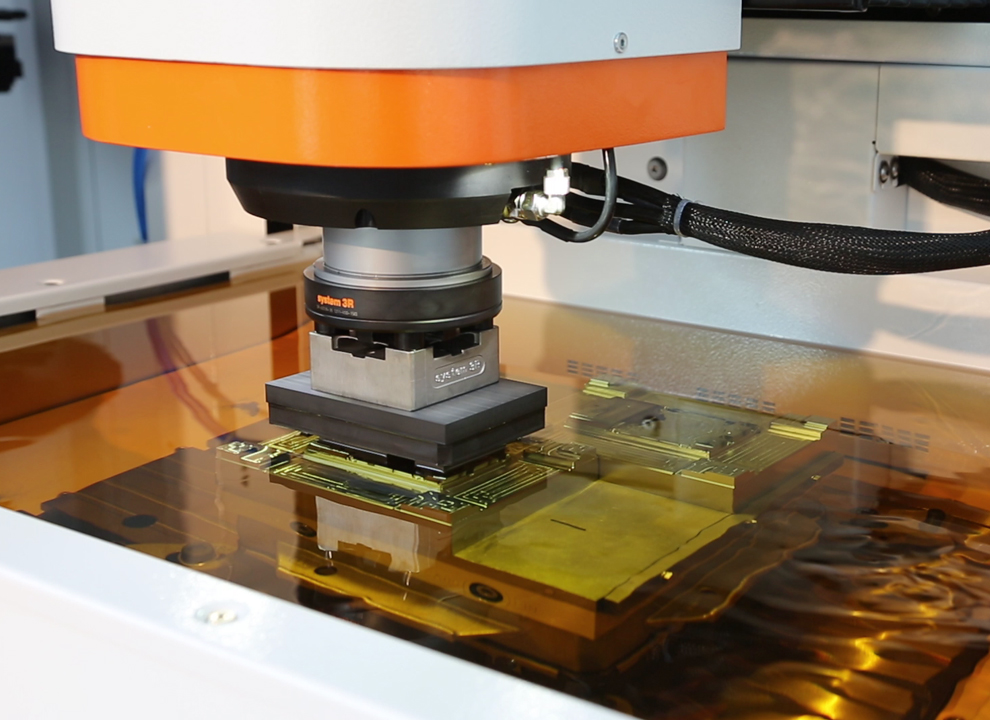

Plunge EDM

Plunge EDM (a.k.a. Sinker EDM) consists of an electrically charged three-dimensional electrode with the workpiece submerged in an insulating fluid. A series of rapidly recurring current discharges erodes the metal on the piece to the desired shape. Plunge EDM can provide a part with tight tolerances and very fine finish.